热敏电阻5D-7:

RT NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第1页,共7页 Pages:No.1of 7 pages | |||||||||||||||||||||||||||||||||

料号编码规则 功率型NTC热敏电阻的产品编码由9位编码组成,其编码规则如下: NTC 07 D 050 M K 5 2 N 1 2 3 4 5 6 7 8 9 料号编码说明

| ||||||||||||||||||||||||||||||||||||||

PART NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第2页,共7页 Pages:No.2 of 7 pages | |||||||||||||||||||||||||||||||||

1. APPEARANCE外观 | ||||||||||||||||||||||||||||||||||||||

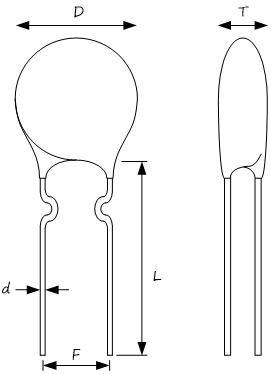

1-1. 尺寸Dimensions (mm)

| 1-2. Marking标志 NTC 5D-7 | |||||||||||||||||||||||||||||||||||||

1-3.Coating包封 □ No coating 无包封 ■ Coating 包封 | ||||||||||||||||||||||||||||||||||||||

Material包封材料

■ PF resin 酚醛树脂 □ Silicon 硅树脂 □ Epoxy 环氧树脂 □ Others 其他 | Color颜色

□ Green 绿色 □ Red 红色 □ Tan 黄色 ■ Black 黑色 □ Blue 兰色 | |||||||||||||||||||||||||||||||||||||

1-4. Leads引线

□ Tin – plated copper wire 镀锡铜线 ■ Tin-plated steel wire 镀锡钢线

□ Straight 直形 □ Axis-formed 轴弯 ■ In-Forming 内弯 □ Out-Forming 外弯

| ||||||||||||||||||||||||||||||||||||||

D:≤8.5 | T:≤5.0 | F:5.0±1.0 | ||||||||||||||||||||||||||||||||||||

d:0.50±0.06 | L:> 25 | |||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||

PART NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第3页,共7页 Pages:No.3 of 7 pages | ||||||

3. INSPECTION检验方法 3-1. Lot Inspection 批量检验 Sampling with IEC410 / DIN ISO 2859-1 (GB/T2828.1-2003) ; Testing with SPEC.NO.:N24-12001 抽样方法按IEC410/ DIN ISO 2859-1 ( GB/T2828.1-2003 ); 试验方法按 SPEC.NO.:N24-12001 | |||||||||||

Item指标项目 | IL | AQL | Item指标项目 | IL | AQL | ||||||

Appearance 外观 | Ⅱ | 0.65 | Rated Zero-Power Resistance 额定零功率电阻 RN | Ⅱ | 0.65 | ||||||

ldering-ability可焊性 | S-2 | 2.5 | Max.Steady State Current 最大稳态电流(A) | S-2 | 2.5 | ||||||

4. STORAGE CONDITIONS存贮环境条件: 4-1.Temperature温度:-10℃~+40℃ 4-2. Humidity湿度:≤70%RH 4-3. Term期限:≤6 months (First-in/ First-out先进先出) 4-4. Place地点: Do not exposing the components to the following conditions, otherwise, it may result in deterioration of characteristics. 不要暴露在下列环境条件下,否则将导致性能衰退或参数飘移: 1) Corrosive gas or deoxidizing gas. 腐蚀性或易氧化气体 2) Flammable and explosive gases. 易燃易爆气体 3) Oil, water and chemical liquid. 油、水和化学溶液 4) Under the sunlight. 太阳光下 4-5. Handling after seal open:After unpacking of the minimum package, reseal it promptly or store it inside a sealed container with a drying agent.

尽量保证开口最小化,立即重新封好,并贮存在密封、带有干燥剂的容器中。

Do not apply the components under the following conditions, otherwise, it may result in deterioration of characteristics, destruction of components or in the worst case, to catching fire. 请不要在下列条件下使用本元件,否则将可能导致产品性能衰退或产品损毁,甚至引发火灾: 1) Exceeding Imax. 超过最大工作电流 2) Exceeding rated temperature range. 超过许可工作温度范围 3) Inferior thermal dissipation (Due to badly inferior thermal dissipation, some part of the components body will become overheated and then be damaged.) 散热不良(由于散热不良,本元件可能因部分过热而导致破坏) | |||||||||||

PART NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第4页,共7页 Pages:No.4 of 7 pages |

6.R/T curve 阻温曲线 | |||||

| |||||

Appendix附录

PART NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第5页,共7页 Pages:No.5 of 7 pages | ||

1. MECHANICAL CHARACTERISTICS机械性能 | |||||||

Item 指标项目 | Specification 技术要求 | Test Conditions & Methods 测试条件/方法 | |||||

1-1. Solder-ability 可焊性 | The terminals shall be uniformly tinned, and its area≥95% 浸润部分上锡均匀,上锡面积≥95% | Dipping the NTC terminals to a depth of 15mm in a soldering bath of 240-245℃ and to the place of 6mm far from NTC body for2-3s (See IEC68-2-20 /GB2423.28 Ta ) 将引出端沾助焊剂后,浸入到温度为240-245℃、深度为15mm的锡槽中锡面距NTC本体下端6mm处,持续2-3秒。(参见IEC68-2-20 /GB2423.28试验Ta) | |||||

1-2. Resistance To Soldering Heat 耐焊接热 | No visible mechanical damage. 无可见损伤 ΔR/RN ≤20% (ΔR =∣RN-RN'∣) | Dipping the NTC terminals to a depth of 15mm in a soldering bath of 265±5℃ and to the place for 6mm below from NTC body for 10±1s.After recovering4-5h under 25±2℃. The rated zero power resistance value RN' shall be measured. (See IEC68-2-20 /GB2423.28 Tb) 根据IEC68-2-20(GB2423 .28)试验Tb进行试验。 采用焊槽法,将引出端沾助焊剂后,浸入到温度为265±5℃、深度为15mm的锡槽中,锡面距NTC本体下端6mm 处,维持10±1秒. 在25±2℃条件下恢复4-5h后,复测额定零功率电阻RN'. | |||||

1-3. Strength of lead terminal 引出端强度 | No break out 无损坏 ΔR/RN ≤20% (ΔR =∣RN-RN'∣) | Fasten the body and apply a force gradually to each lead until 10N and then keep for 10sec, Hold body and apply a force to each lead until 90°slowly at 5N in the direction of lead axis and then keep for 10sec, and do this in the opposite direction repeat for other terminal. After recovering 4~5h under 25±2℃, the rated zero power resistance value RN' shall be measured. (See IEC68-2-21/GB2423.29 Ua / Ub) 根据IEC68-2-21(GB2423 .29)试验U进行试验。 试验Ua:拉力10N,持续10 S; 试验Ub:弯曲90°,拉力5N,持续10 S; 扭转180°,拉力5N,持续10 S。 在25±2℃条件下恢复4~5 h后,复测额定零功率电阻RN' | |||||

PART NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第6页,共7页 Pages:No.6 of 7 pages | ||

2.ELECTRICAL CHARACTERISTICS电气性能 2-1.Test Conditions & Method 测试条件/方法 | |||||||

Items 指标项目 | Spec. 技术要求 | Test Conditions & Methods 测试条件/方法 | |||||

2-1-1.Rated Zero-Power Resistance 额定零功率电阻 RN (W) | 5±20% | Ambient temp. Range:25℃±2℃(TA). Testing voltage:1.5VDC After placing for 1~2 hours under TA, the resistance value shall be measured. 环境温度 TA:25℃±2℃ 测试电压:1.5VDC 在常温TA条件下,放置1~2小时 后测得阻值RN。 | |||||

2-1-2.Thermal Dissipation Constant 热耗散系数d (mW/°C) | ≥11 | The thermal dissipation constant(d) could be calculated by the ratio of a change in power dissipation(DP) of the thermistor to a change in temperature(DT) of the thermistor at a specified ambient temperature 在特定的环境温度下,热耗散系数(d)为热敏电阻电功率消耗(DP)与本体温度变化量 (DT)的比值. | |||||

2-1-3.Thermal Time Constant 热时间常数 t (s) | ≤34 | The time(t) shall be measured within which the temperature change of NTC thermistor is reached at 63.2% of the ambient temperature change under zero power condition 热时间常数(t)为在零功率条件下,热敏电阻的温度下降到其最初温度与最终温度之差为63.2% 时所需要的时间 | |||||

2-1-4.Material Constant 材料常数 B (K) | 2600±5% B=T1T2/(T2-T1)×Ln(R1/R2) | R1 , R2 is zero-power resistance at T1 , T2 R1 , R2 分别为T1 , T2温度下的零功率电阻 T1 = 298.15K(25℃) T2 = 358.15K(85℃) | |||||

2-1-5.Max.Steady State Current 最大稳态电流(A) | 2.0A No visible mechanical damage. 无可见损伤 ΔRN / RN≤20% (ΔR =∣RN-RN'∣) | Ambient temp. Range环境温度:25℃±2℃. Testing Current 测试电流:3.0A | |||||

PART NO. 料 号 | NTC07D050MK52N | 5D-7 | REV NO. 版 本 | 0/A | 页次:第7页,共7页 Pages:No.7 of 7 pages | ||

3. Reliability Test 可靠性试验(周期性检测项目) | |||||||

Items 指标项目 | Spec. 技术要求 | Test Conditions & Methods 测试条件/方法 | |||||

*3-1. Temp. Cycling Testing 温度循环测试 | No visible mechanical damage. 无可见损伤 ΔRN / RN ≤20% (ΔR =∣RN-RN'∣) | Ta:-40±3℃/ 30min→25±2℃/ 5min→ Tb:150±3℃/ 30min→25±2℃/ 5min Cycles:5times After recovering 4~5 h under 25±2℃, the rated zero power resistance value RN' shall be measured. 在Ta=-40±3℃和Tb=150±3℃的环境温度中各存放30分钟, 循环5次.每次高低温循环都有在25±2℃的环境中过渡5分钟。 样品进行温度循环测试后,取出放置室温(25±2℃)4~5小时后测量零功率电阻RN'. | |||||

*3-2. Electrical Cycling Testing 电循环测试 | No visible mechanical damage. 无可见损伤 ΔRN / RN ≤20% (ΔR =∣RN-RN'∣) | Ambient temp. Range:25℃±2℃. Cycles:2,000times On / Off:5 s / 55 s Test Current3.0A After recovering 4~5h under 25±2℃, the rated zero power resistance value RN' shall be measured. 环境温度:25℃±2℃. 循环次数:2,000次 通/断:5 s / 55 s 测试电流:3.0A 样品置于室温(25±2℃)4~5小时后,测量其零功率电阻RN'. | |||||

*3-3.LoadLife ( Endurance ) Testing 持久性测试 | No visible mechanical damage. 无可见损伤 ΔRN / RN ≤20% (ΔR =∣RN-RN'∣) | Ambient temp. Range:25℃±2℃;3.0A/ 1,000±24h After recovering 4~5 h under 25±2℃, the rated zero power resistance value RN' shall be measured. 环境温度:25℃±2℃. 样品通过最大工作电流3.0A , 1,000±24小时后,取出置于室温(25±2℃)4~5小时后,测量其零功率电阻RN'. | |||||

*3-4. Humidity Testing 耐湿性测试 | No visible mechanical damage. 无可见损伤 ΔRN / RN ≤20% (ΔR =∣RN-RN'∣) | Ambient temp. range :40℃±2℃ R.H.:93±3% , Energized time:1000±24 h After recovering 4~5 h under 25±2℃, the rated zero power resistance value RN' shall be measured. 在温度40±2℃,相对湿度 93±3%的环境中放置 1000±24 小时后,取出置于室温(25±2℃)4~5小时后, 测量其零功率电阻RN'. | |||||

English

English